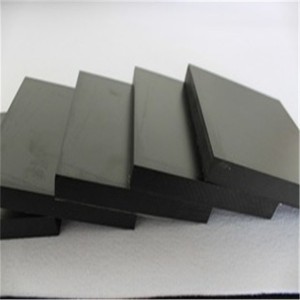

Ceramic top

There are various kinds of fworktops for your selection except the kinds as below:

| Attribute | Lab-grade phenolic resins worktop | Epoxy resin worktop | Ceramic worktop |

| Ingredient | Dipping phenolic resin into special multi-layer kraft paper, it’s hot-solid formed under high temperature and pressure. | Quartz sand and epoxy mixed with special bond. | Combined clay, kaolin and feldspar mixed with many special material. |

| Corrosive-resistance | It’s resistant for many kinds of acid, alkali, solvent and reagent etc. | It’s resistant for many kinds of acid, alkali, solvent and reagent etc. | Excellent |

| Heat- resistance | Normal:135℃it couldn’t touch flame directly. | 600℃ heat resistance | 1000℃ heat resistance |

| Colour | Black, gray, dark green | Gray, green | Black, gray, white, green |

| Worktop thickness | 12.7mm, 16mm, 19mm | 16mm, 19mm, 25mm | 20mm |

| Water-resistant | Water absorption:0.6% | Water absorption:0.008% | Excellent |

| Physics feature | Good | Good | Excellent |

| Forbidden Reagent | There are little defects after meeting with 65% nitric acid, chromic acid, hydrofluoric acid. There are defects after meeting with 98% sulfuric acid. | There are little defects after meeting with 98% sulfuric acid, cleaning solution of heavy chromic acid, 40% chromic acid, 50% sodium hydroxide. | _ |

| Test method | For many medicine with fixed hydrocarbon: dripping it on the worktop directly; for medicine with volatility:Infiltrating it into absorbent cotton still saturated state and touching with desktop, after that it should be covered by visual glass or jar; Above medicine should be placed on the desktop at 25℃ room temperature, after 16 to 25 hours the desktop should be washed with soap and water. At last it can be tested and evaluated when the desktop is dried. | ||